Standard float switches with two switching points

Standard float switches with two switching points

Hardly any process in industry or trade could be imagined without a continuous level monitoring system. The demands to sensors are rising as a result of the ever increasing automation.

Our standard float switches with two switching points are often used in tank systems. It is irrelevant here whether, for instance, the filling level of an oil tank or the level of a cistern has to be measured. That way, the filling level in the most different points of a silo or tank can be measured and monitored.

As the float switches can be configured to perfectly suit your needs, they can be easily integrated into your application.

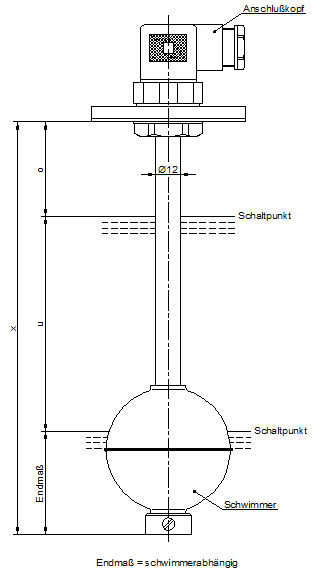

More than one float body may be required depending on switching demands. We usually use one float body for a maximum of two switching points to achieve a bistable switching behaviour. Thus, the signal can be preserved even if the filling level falls or rises.

Product features:

The connecting head

The connecting head can be configured as a simple cable outlet up to and including an R2" thread

Enclosure

Our range of products also includes flanges in standard sizes, with or without enclosure

Variant

Models made of stainless steel (mat. no. 1.4571), brass (mat. no. 2.0321) and PVC available

Length

Switching tube up to 3 m in length

Plug

Connection by means of cable or plug

Form

Straight or curved versions available

Material

The float body material ranges from PVC, PP, POM, NBR to stainless steel, depending on the respective need